What is Pond Aeration

Pond aeration, achieved through water agitation, enhances dissolved oxygen levels crucial for a healthy aquatic ecosystem. This process involves natural or mechanical means to bring water into contact with the air.

Types of Aeration

ClearBlu offers Aeration for wastewater or freshwater. The process for these differs and therefore it’s important to work with a company who’s experienced with that type of Aeration.

Wastewater Aeration

Find out how our state of the art microbubble aeration technology can increase your efficiency rate and digest sludge.

Freshwater Aeration

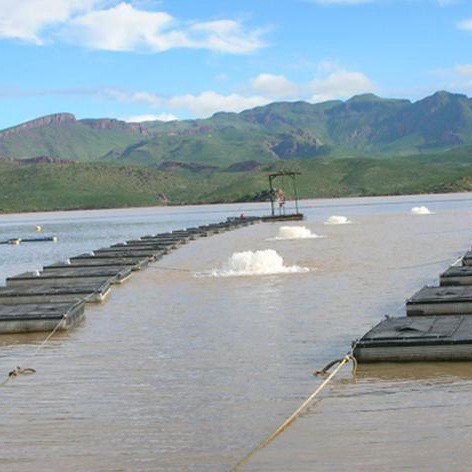

Aeration techniques are commonly used in pond, lake, and reservoir management to address low oxygen levels or algal blooms.

Pond Treatment Process

Our pond treatment process is desirable over anaerobic digestion because it is fast, odor-free, and prevents the need for any solids removal procedures. Aerobic digestion is desirable over DAF systems because it eliminates the need for costly chemical use and disposal.

ClearBlu uses a unique aeration technology known as micro bubble aeration, to achieve an aquatic environment that supports a bacteria population capable of complete digestion. This is the key difference over conventional technologies.

Benefits of Micro Bubble Aeration

- Higher and faster removal rate of BOD and TSS

- Up to 70% reduction in electrical consumption

- Elimination of odors

- Improvement of water quality

- Rapid microbial growth and reproduction

- Elimination of pathogens

- Control of algae growth

Our Micro Bubble Technology

What sets this aerator apart is in the size of the bubbles. Through years of research and field tests, we have taken micro bubble technology to a new level. The Ultra Fine Bubble (UFB) unit produces a bubble size of 0.02 mm or less in a negative pressure environment. That’s over 1 billion micro bubbles per cubic foot which translates to over 1,000 square feet of surface area of oxygen molecules.

Conventional Aeration vs Microbubble Technology

As compared to conventional aeration technology, microbubble aeration produces an exponentially greater oxygen source which is denser and longer lasting in water. This allows the volume of healthy bacteria to increase, resulting in the more effective elimination of waste products and bad odors.

This technology introduces micro bubbles into the water without causing excessive agitation to the water through the use of low-pressure air. This is important because high turbulence is counterproductive to aerobic digestion. It has been shown that aerobic bacteria fixed to a submerged surface within low turbulence, oxygen-rich environment is up to 10 times more efficient at digesting organic matter.

Our Aeration Equipment

he ClearBlu Microbubble Aerator, instead of using the compressed air/fine pore system, uses a patented process to create bubbles in a partial vacuum. The small bubbles created in this process average 0.025 mm in diameter. The small size of the bubble and the low-pressure gas it holds to create a small buoyance force that is so small that it is less than the surrounding surface tension of the water.

The bubble, in fact, does not rise to the surface but remains suspended in the fluid. This makes all of the oxygen in the bubble available to be dissolved in the liquid as needed. In addition, the Brownian Effect drives the bubbles to the bottom of tanks or ponds creating a top-to-the-bottom aerobic condition.-