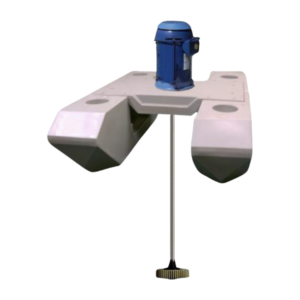

AF Series Surface Aerators

Kasco Surface Aerators lead the market with more installations than any other manufacturer. In an independent study by Auburn University, Kasco Aerators were found to deliver up to 3.0 lbs of oxygen per horsepower per hour of operation, proving them to be some of the most efficient and effective units on the market. Built for dependable, continuous operation, these freshwater aeration products have a proven record in a multitude of applications, ranging from ponds and lakes to salt water and other corrosive environments. Other applications include:

- Commercial aquaculture

- Agricultural ponds

- Industrial plants

- Municipal waste water

- Backyard ponds

All Kasco Surface Aerators are self-contained, lightweight units that float at the surface. With just two or three mooring lines anchoring the unit and a single power cord running to shore, these units are easily installed and maintained by a single person.