WASTEWATER TREATMENT 101: the Process and its importance

Every facility that uses water needs an effective wastewater treatment system to manage and treat what’s left behind. From food processing and manufacturing to agriculture and energy production, ClearBlu Environmental, designs industrial wastewater treatment systems that not only meet strict discharge requirements but also support sustainability and cost savings.

In this guide:

What is wastewater treatment?

In the simplest terms, wastewater treatment is the process of removing contaminants from used water so it can be safely reused, recycled, or discharged into the environment. Wastewater can contain:

- Suspended solids and oils

- Organic materials

- Nutrients such as nitrogen and phosphorus

- Chemicals and heavy metals

The goal of wastewater treatment is to separate and neutralize these contaminants before they cause harm to waterways, soil, or ecosystems.

Why Industrial Wastewater Treatment Matters

Industrial wastewater treatment goes beyond basic sanitation. In manufacturing, food processing, or energy production, untreated wastewater can:

- Damage local ecosystems by introducing harmful chemicals or excess nutrients

- Increase operational costs through fines, surcharges, or higher disposal fees

- Harm equipment via corrosion or buildup from solids and fats, oils, and grease (FOG)

- Waste valuable resources that could otherwise be recycled back into production

By implementing proper treatment, companies reduce environmental impact and strengthen compliance with EPA and local discharge regulations, often improving their bottom line in the process.

The 3 Key Stages of Wastewater Treatment

Every treatment system is designed around three fundamental stages. ClearBlu Environmental custom-engineers these stages based on each facility’s unique wastewater profile.

- Primary Treatment

- The first step is to remove large solids and debris. Equipment such as settling tanks, 3-phase separators, and waterfall screens capture heavier particles, fats, and oils before they can clog or damage downstream systems.

- Secondary Treatment

- Once the bulk solids are removed, microorganisms break down organic material and nutrients. Aeration systems and biological reactors convert waste into stable compounds, reducing biochemical oxygen demand (BOD) and chemical oxygen demand (COD).

- Tertiary Treatment

- The final stage focuses on filtration and disinfection. This step ensures the water meets required purity levels for reuse, irrigation, or discharge. Depending on the application, this can involve ultrafiltration, UV disinfection, or chemical polishing.

Common Industrial Wastewater Challenges

Different industries face unique treatment obstacles:

- Food & Beverage: High levels of FOG, organic load, and variable pH

- Agriculture: Sediment, nutrients, and pesticide runoff

- Manufacturing: Metals, solvents, and suspended solids

- Energy Production: High salinity and temperature variance

ClearBlu’s modular designs allow systems to be tailored for these challenges ensuring reliable performance even in demanding industrial environments.

Sustainable Wastewater Management

Modern industrial wastewater treatment isn’t just about compliance, it’s about conservation. By reusing treated water for cooling, irrigation, or process rinse, companies can reduce freshwater demand and strengthen sustainability initiatives.

ClearBlu Environmental incorporates energy-efficient pumps, stainless steel components, and biological treatment systems that minimize chemical use and extend equipment lifespan.

🫱🏻🫲🏽Partner with ClearBlu Environmental

At ClearBlu Environmental, we combine engineering expertise with a deep understanding of biological and mechanical treatment systems. Our goal is to help facilities meet discharge limits, protect the environment, and recover value from their wastewater.

34 Billion

gallons of wastewater processed in the United States every day (UN Water)

50%+

of food & beverage facilities water is used to clean equipment (EPA)

211 m³

of wastewater produced per person each year in North America

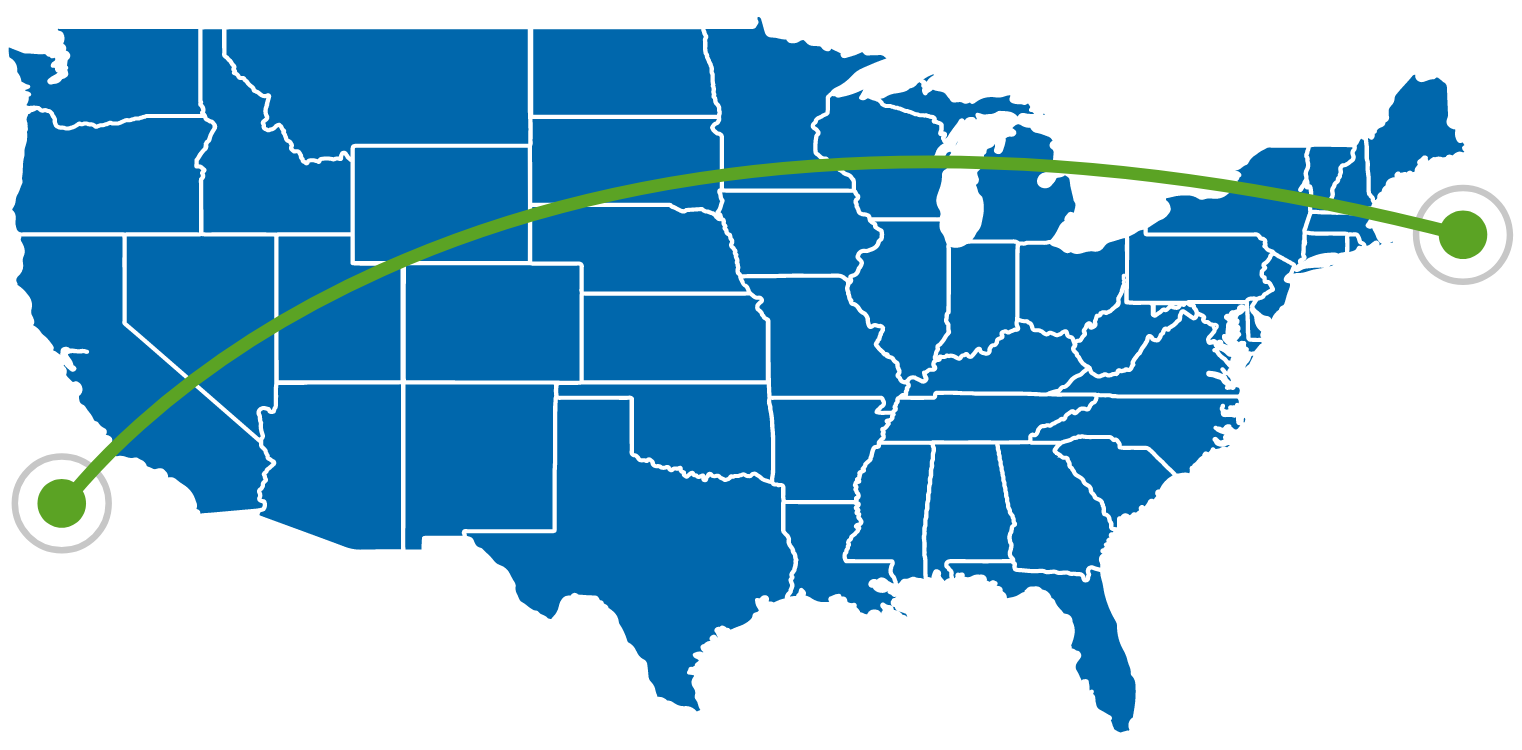

CONVENIENT LOCATIONS

Serving Companies Nationally

With locations in California, Colorado, and Oregon, we are able to provide wastewater treatment solutions across the United States.