CASE STUDIES

paso robles winery

See how we helped a custom crush facility stop discharging process wastewater into leach fields.

Background

The Winery approached ClearBlu to add a treatment system that would treat the wastewater to the necessary levels for land application. The Winery had lift stations that pumped process wastewater to a rotary drum screen that removed solids.

Solution

ClearBlu designed a retrofit to the system that used the existing lift station and rotary screen. ClearBlu installed an automatic pH unit on the existing pre-treatment pad with the rotary screen.

Treatment is done in poly tanks with nano-bubble aeration and spraybars in the tanks control foaming generated in the aerobic treatment process. The nano-bubble generator uses pure oxygen to deliver five times more oxygen to microbes in the water. Outside of harvest, the Winery can use atmospheric air instead of oxygen to reduce operational costs. The tanks are accessible with a catwalk for service and maintenance. The Winery had a storage tank that was repurposed in the system design as a finish water tank for pumping treated wastewater to the irrigation system.

results

The treatment system is designed for a peak daily flow of 5,000 gallons during harvest and 7,000 mg/L BOD. With nano-bubble aeration and microbes, the Winery is able to reduce to the necessary levels for irrigating its vines.

Because the winery does not have a specialist to operate a treatment system, ClearBlu provides monthly service. The winery performs a short daily checklist, must is not required to perform any maintenance or operation duties.

CONTACT US

TALK WITH AN EXPERT

We have a cost-effective and environmentally friendly solution for breweries of all shapes and sizes in the United States.

Contact Us – Sidebar

Related CASE STUDIES

Conn Creek Winery

Project Type: Primary Treatment

Equipment: Wastewater Aeration

Learn More

Daou Vineyards and Winery

Project Type: Primary Treatment

Equipment: Lift Stations; Waterfall Screens; pH Balancing; Settling Tanks

Learn More

Jordan Winery

Project Type: Primary Treatment

Equipment: Wastewater Aeration; Microbes

Learn More

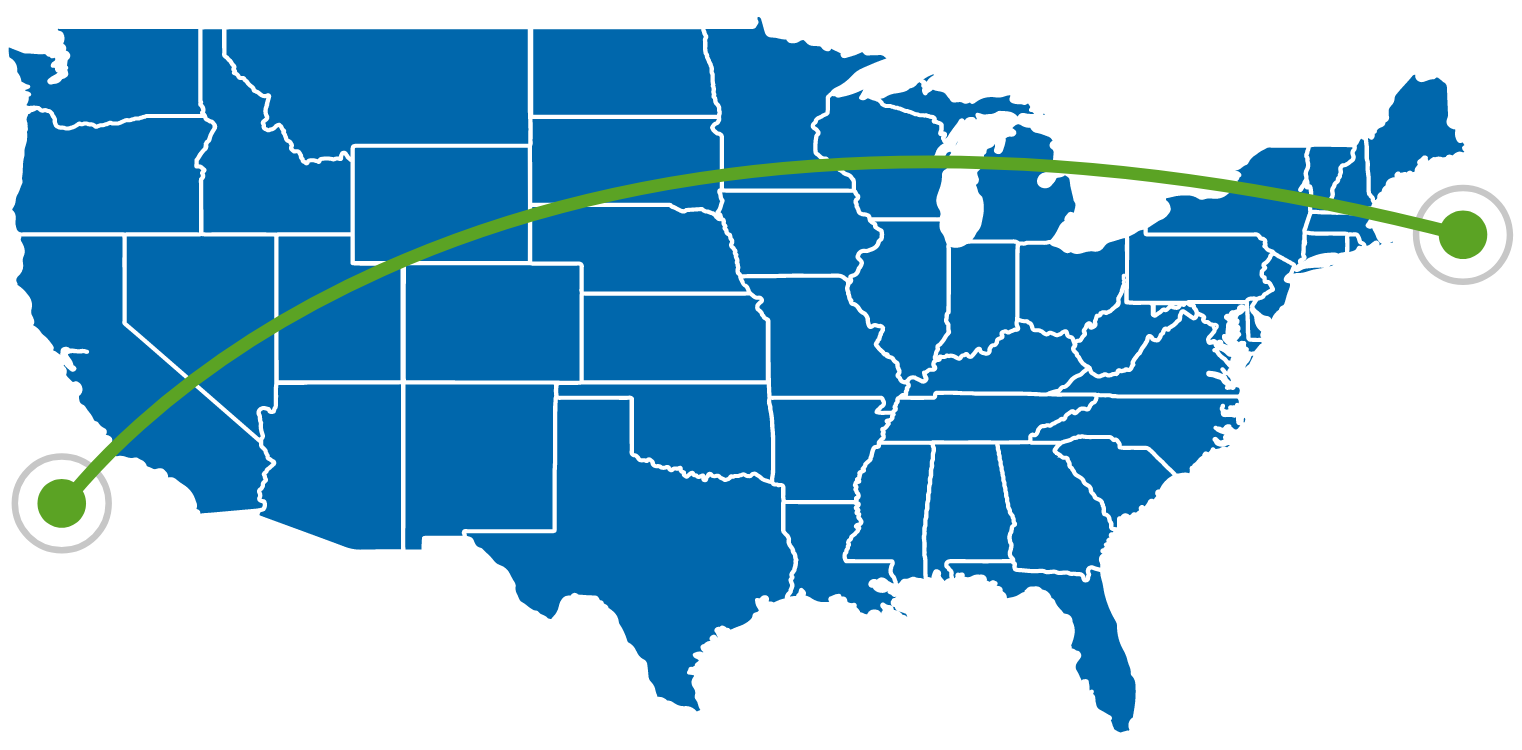

CONVENIENT LOCATIONS

Serving Companies Nationally

With locations in California, Colorado, and Oregon, we are able to provide wastewater treatment solutions across the United States.