Our equipment

POND TREATMENT POND AERATION SOLUTIONS

At ClearBlu Environmental, we focus on complete aerobic digestion of organic waste and provide treatment for ponds.

What is pond aeration?

Pond aeration, achieved through water agitation, enhances dissolved oxygen levels crucial for a healthy aquatic ecosystem. This process involves natural or mechanical means to bring water into contact with the air.

We offer aeration for wastewater or freshwater. The process for these is different and requires treatment in different ways. Working with a company that has experience in that type of aeration is important for the best success.

Our pond treatment process

Our aerobic pond treatment process is desirable over anaerobic digestion. Aerobic treatment is fast, odor-free, and prevents the need for any solids removal procedures. Aerobic digestion is desirable over DAF systems because it eliminates the need for costly chemical use and disposal.

ClearBlu uses a unique aeration technology known as micro bubble aeration. This achieves an aquatic environment that supports a bacteria population capable of complete digestion. This is the key difference over conventional technologies.

Benefits of Micro Bubble Aeration:

- Higher and faster removal rate of BOD and TSS

- Up to 70% reduction in electrical consumption

- Eliminates odors

- Improvement of water quality

- Rapid microbial growth and reproduction

- Eliminates pathogens

- Control of algae growth

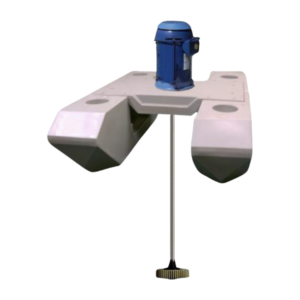

our Microbubble Technology

What sets our aerator apart is in the size of the bubbles. Through years of research and field tests, we have taken micro bubble technology to a new level. The Ultra Fine Bubble (UFB) unit produces a bubble size of 0.02 mm. This number is even less in a negative pressure environment.

That means over 1 billion micro bubbles per cubic foot, equaling over 1000 square feet of oxygen molecules.

CONTACT US

TALK WITH AN EXPERT

We have cost-effective and environmentally friendly pre-treatment solutions of all types. Helping companies all over the United States find the perfect sized system.

Contact Us – Sidebar

Types of aeration

FAQS

What are the benefits of using Micro Bubble Aeration?

Benefits include:

- Higher and faster removal rate of BOD and TSS

- Up to 70% reduction in electrical consumption

- Eliminates odors

- Improvement of water quality

- Rapid microbial growth and reproduction

- Eliminates pathogens

- Control of algae growth

What is the difference between Conventional Aeration and Microbubble Technology?

Compared to conventional aeration technology, microbubble aeration produces an oxygen source that is much greater. The source is also denser and longer lasting in water. This allows the volume of healthy bacteria to increase and more effectively removing waste products and bad odors.

This technology introduces micro bubbles into the water without causing extra agitation to the water. High turbulence works against the aerobic digestion process, so this is another benefit. Aerobic bacteria fixed to a submerged surface within low turbulence & oxygen-rich environment is up to 10x more efficient at digesting organic matter.

What is ClearBlu’s pond treatment process?

Our pond treatment process is fast, odor-free, and prevents the need for any solids removal procedures. This makes it a better choice than anaerobic digestion and DAF systems. Aerobic digestion eliminates the need for costly chemical use and disposal.

ClearBlu uses a unique aeration technology to achieve a bacteria population capable of complete digestion. This is the key difference over conventional technologies.

national experts

Have more questions, or need to help deciding which equipment is right for you? Our team would love to assist with your project.

OUR Services

1

Design/Engineer

We redesign aeration systems to fit, or design completely new systems. We also work with regulatory agencies, contractors, architects, and engineers to ensure smooth water treatment.

2

Supply/Build

We manufacture screening, pH balancing, and biodigestion systems and source other industry-leading equipment to build complete wastewater treatment solutions emphasizing aerobic digestion.

3

Install

We offer complete system installation and training. We’ll manage systems integration and make sure everything is working as intended.

4

Service

We provide service contracts to maintain equipment and keep it running to reduce downtime. We guarantee everything we design and install. If your equipment requires service, simply reach out.

CASE STUDIES

See how ClearBlu has assisted the following businesses with pond aeration and treatment.

Bergfeld Vineyards

Wineries

Project Type: Primary Treatment

Equipment: Wastewater Aeration

Learn More

Castoro Cellars

Wineries

Project Type: Primary Treatment

Equipment: Biodigesters; Freshwater Aeration; Wastewater Aeration

Learn More

Jordan Winery

Wineries

Project Type: Primary Treatment

Equipment: Wastewater Aeration; Microbes

Learn More

equipment Videos

Aerobic Digestion

Walk through the full aerobic digestion treatment process for wastewater. See how ClearBlu’s system can save you money, time, and efficiency.

Watch Video

Fine Bubble Defuser

Learn about our Ultra Fine Bubble (UFB) unit that produces a bubble size of 0.02 mm or less in a negative pressure environment. See how it stacks up against a conventional system.

Watch Video

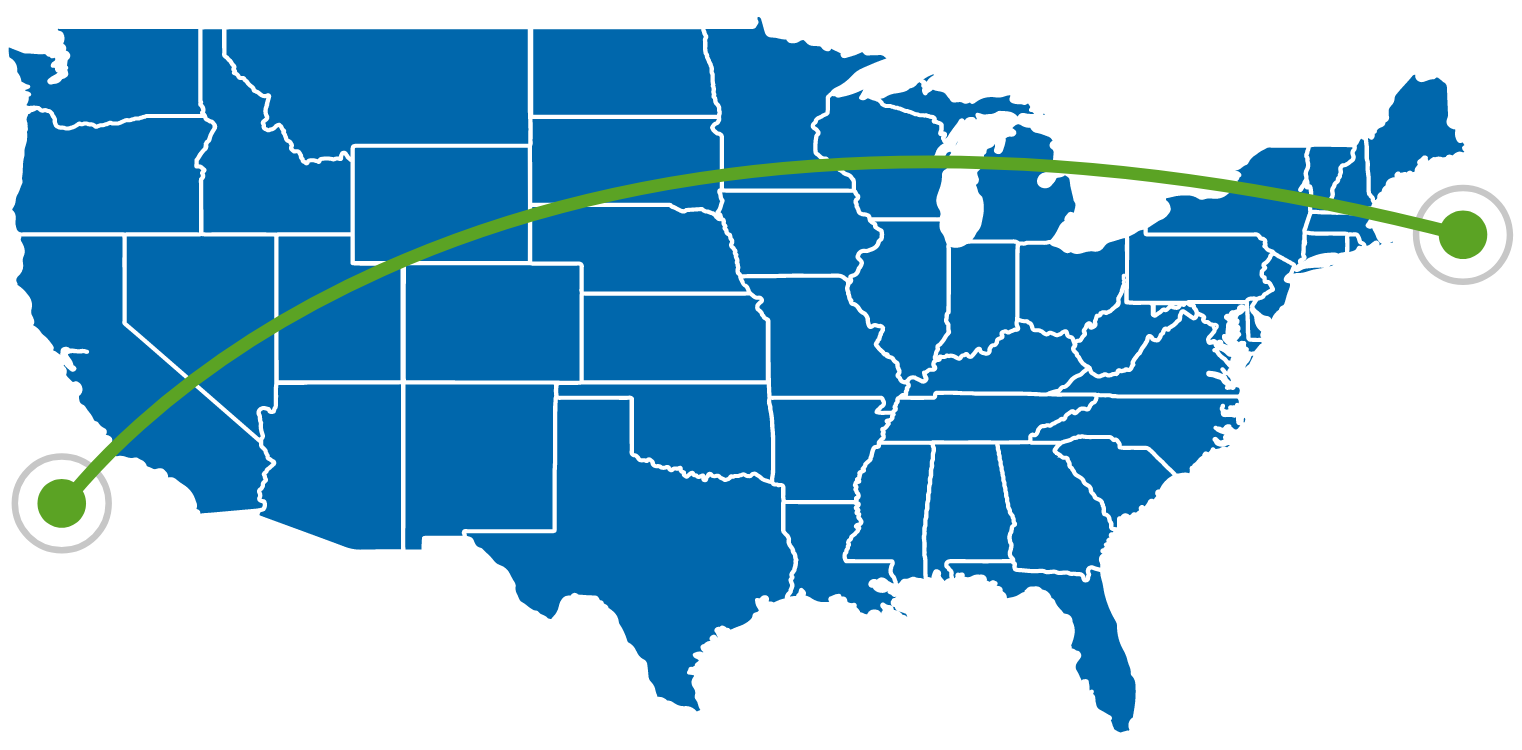

Convenient Locations

Serving Companies Nationally

With locations in California, Colorado, and Oregon, we are able to provide wastewater treatment solutions across the United States.

SERVICE // INSTALL // SUPPLY // BUILD // DESIGN

SERVICE // INSTALL // SUPPLY // BUILD // DESIGN

SERVICE // INSTALL // SUPPLY // BUILD // DESIGN

SERVICE // INSTALL // SUPPLY // BUILD // DESIGN