About Screw Presses

The screw press sludge dewatering machine is clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of plant construction. The system utilizes the screw and the moving rings to clean itself as a clog-free system and is controlled by a PLC. it’s a technology that can replace the traditional filter press such as a belt press and frame press. The

screw speed is very low, so has low power consumption as well as water consumption in contrast to a centrifuge. The system utilizes polymers with automatic dosing control.

Equipment Required

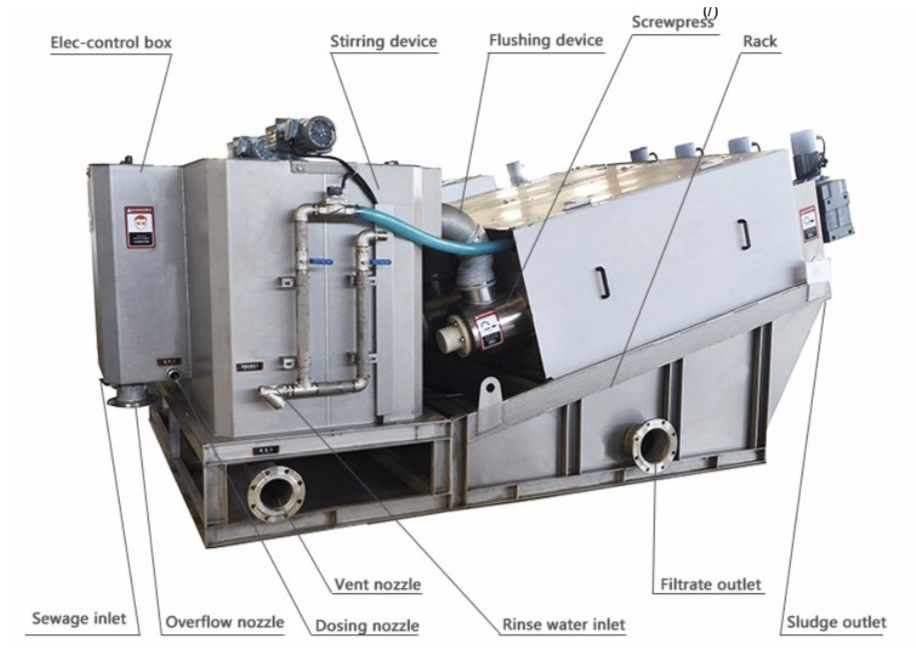

The Sludge Dewatering Press can be provided with all equipment required for dewatering included and factory mounted, piped, and wired on a single stainless steel skid. This equipment includes the sludge pump, wash water pump, polymer dosing system and control panel. The system features fully automated one pushbutton startup and shutdown. Once started up the system can run unattended and can be set to shutdown automatically with no operator intervention.

Complete System

The Sludge Dewatering Press offers a completely operational, skid mounted and self-contained system which can include:

- Screw Press

- PLC Controls

- Sludge Pumps

How It Works

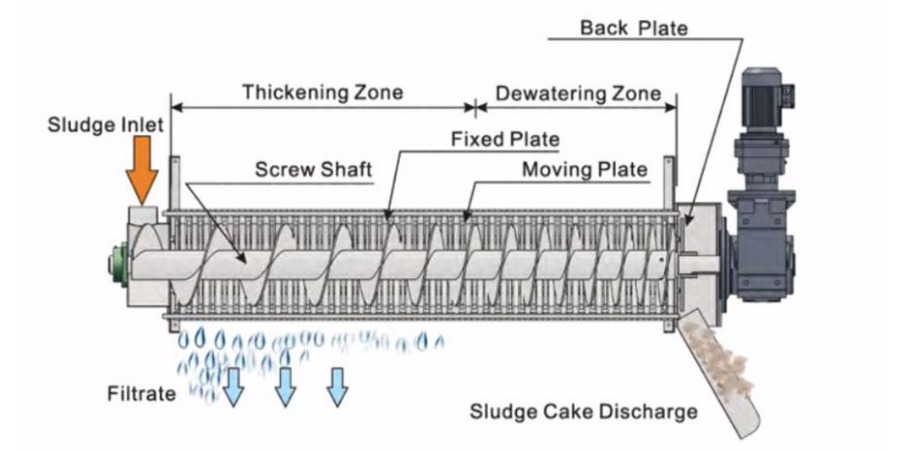

Force & water concurrent

The force and water work in the same direction to make the free water separated with the fastest speed.

Moderate pressure

Maintain the lowest energy consumption and mechanical wear while ensuring the sludge dewatering effective,

Thin-layer dewatering

Dewatering with thin layer makes the free water separated with the fastest speed.

Extension the dewatering path

To allow enough time and continuous operation in dewatering.

Benefits & Features

- Enclosed to minimize odors and noise

- Very low wash water usage(1/8 compared with belt press)

- Very low power consumption(1/20 compared with a centrifuge)

- High cake solids

- Minimal operator requirement

- Easy to operate and maintain

- Auto start-up, run, and shutdown

- Touch screen operation optional

- Sludge Flow and Cake Monitoring System

- Available with many other options like Dairy, Palm Oil, etc.

|

Model |

DS Throughput (kg/h) |

Sludge flow (m3/h) |

||||

|---|---|---|---|---|---|---|

|

Low Concentration |

High Concentration |

10000 mg/l |

20000 mg/l |

25000 mg/l |

50000 mg/l |

|

|

KTDL 131 |

5 |

10 |

0.5 |

0.5 |

0.4 |

0.2 |

|

KTDL 132 |

10 |

20 |

1 |

1 |

0.8 |

0.4 |

|

KTDL 133 |

15 |

30 |

1.5 |

1.5 |

1.2 |

0.6 |

|

KTDL 251 |

15 |

30 |

1.5 |

1.5 |

1.2 |

0.6 |

|

KTDL 252 |

30 |

60 |

3 |

3 |

2.4 |

1.2 |

|

KTDL 253 |

45 |

90 |

4.5 |

4.5 |

3.6 |

1.8 |

|

KTDL 301 |

30 |

60 |

3 |

3 |

2.4 |

1.2 |

|

KTDL 302 |

60 |

120 |

6 |

6 |

4.8 |

2.4 |

|

KTDL 303 |

90 |

180 |

9 |

9 |

7.2 |

3.6 |

|

KTDL 304 |

120 |

240 |

12 |

12 |

9.6 |

4.8 |

|

KTDL 351 |

50 |

100 |

5 |

5 |

4 |

2 |

|

KTDL 352 |

100 |

200 |

10 |

10 |

8 |

4 |

|

KTDL 353 |

150 |

300 |

15 |

15 |

12 |

6 |

|

KTDL 354 |

200 |

400 |

20 |

20 |

16 |

8 |

|

KTDL 401 |

80 |

160 |

8 |

8 |

6.4 |

3.2 |

|

KTDL 402 |

160 |

320 |

16 |

16 |

12.8 |

6.4 |

|

KTDL 403 |

240 |

480 |

24 |

24 |

19.2 |

9.6 |

|

KTDL 404 |

320 |

640 |

32 |

32 |

25.6 |

12.8 |

Have Questions?

Talk to one of our experts about the available screw presses by contacting us.